New installation at SCEA DENIEUL

On September 8, 2023, SCEA DENIEUL held an open house. The day was an opportunity to present in detail the advanced facilities and equipment at the pig farm. The building

On September 8, 2023, SCEA DENIEUL held an open house. The day was an opportunity to present in detail the advanced facilities and equipment at the pig farm. The building

A look back at SARL LANGLAIS’s open house. 450 sows farrowing-to-finishing With its new 1680-place fattening building, SARL LANGLAIS demonstrates its commitment to technology and animal performance. From birth, each

Installation in the Manche (50 – France) at SCEA LEHERICEY by our technical partner ATS. – 84 Materneo dispensers in Farrowing building to replace the existing feeding system. – 1

First soup installation for this ANTAI customer, HEFEI province (CHINA) with a building of 6,000 fattening places from 25 to 120 kg. This building is equipped with an MD2 system

Installation at SCEA Ville Ory in the township of Plouasne at the home of Mr and Mrs DARTOIS. Equipment on the livestock section : Equipment on the energy part :

First farm of the island equiped with Maternéo & Selfifeeder GES !Back in photos to the open house day of June 23, 2022 on the island of Reunion at EARL

“A career project based on the optimization of production costs and the valorization of its products.” A farm equipped with the Multifeeder concept to manage the sows liquid feed, and

On Friday, April 1st, Arnaud JOLLY, breeder in Plaintel (22) opened the doors of his farm to present his new 1200 places fattening building. Building on straw BIO model with

New fitting for ASSERVA ! Finishing touches on the soup machine of the Gaec de la Croisière in the Orne department.Installation of the soup machine, pre-soup and cereal grinding with

Segoviano New installation for Asserva in Spain in the Cochinillo Segoviano farm located in the Segovia region.A farm with a capacity of 630 sows with 114 farrowing places and a

We would like to thank our client, Valery BERTRAND – SCEA DU RIEUX for the confidence shown in the Asserva and Asserva Energies team, regarding the installation of equipment in

Asserva fitted at ghent university, with 10 aqualab stations with animal weighing. The building consist of 10 crate of 15 piglets.The piglets will be brought in at 7 kgs and

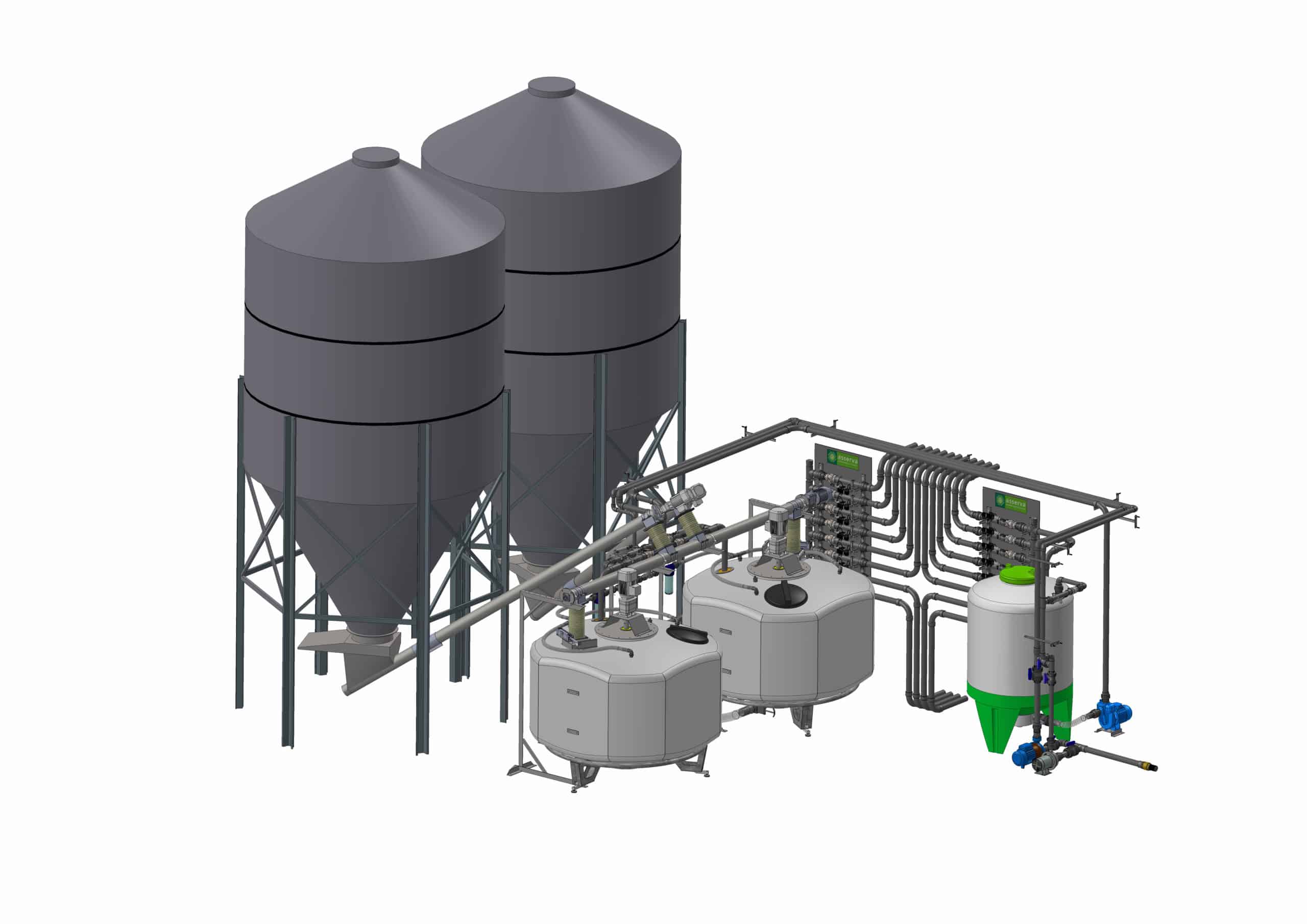

New fitting in Spain for Asserva Installation of the Optimat Air concept – Multiphase pneumatic transfer in the Los Cortijos farm with 18 rooms for 21,000 piglets from 6 to

The ASSERVA development in China still going in the good way, the chinese farmers and the the chinese livestock companies request new solutions and high technologies. ASSERVA company takes market

After some weeks of installation, the liquid feeding system for 20 000 fatteners is now under commissioning by our chinese ASSERVA technician. The system is divided in 2 parts with 2

Asserva is really proud to be the official supplier for Intelligent feeding system into Panda Pig park. This farm is based at Jinhua in Zhejiang province (South East of China,

By the end of the decade at the latest, all the pig farms in Canada will have to follow the new regulations regarding animal welfare. In particular, gestating sows will

The Asserva sales team was invited to visit an impressive new project, on the farm La Rabardière, in Brielles (France). This 3 000 weaning places building is equipped with the pneumatic

We had the pleasure to ship a large liquid feed installation for an Important Chinese customer. The multifloor buildings will welcome 20 000 fatteners. The Multifeeder liquid feed installation will

Jolco, the local distributor of the Asserva solutions in Quebec, recently commissioned the Materneo system in the Porc du Moine farm. Located in Plessiville, this farrow-to-finish family farm of 520

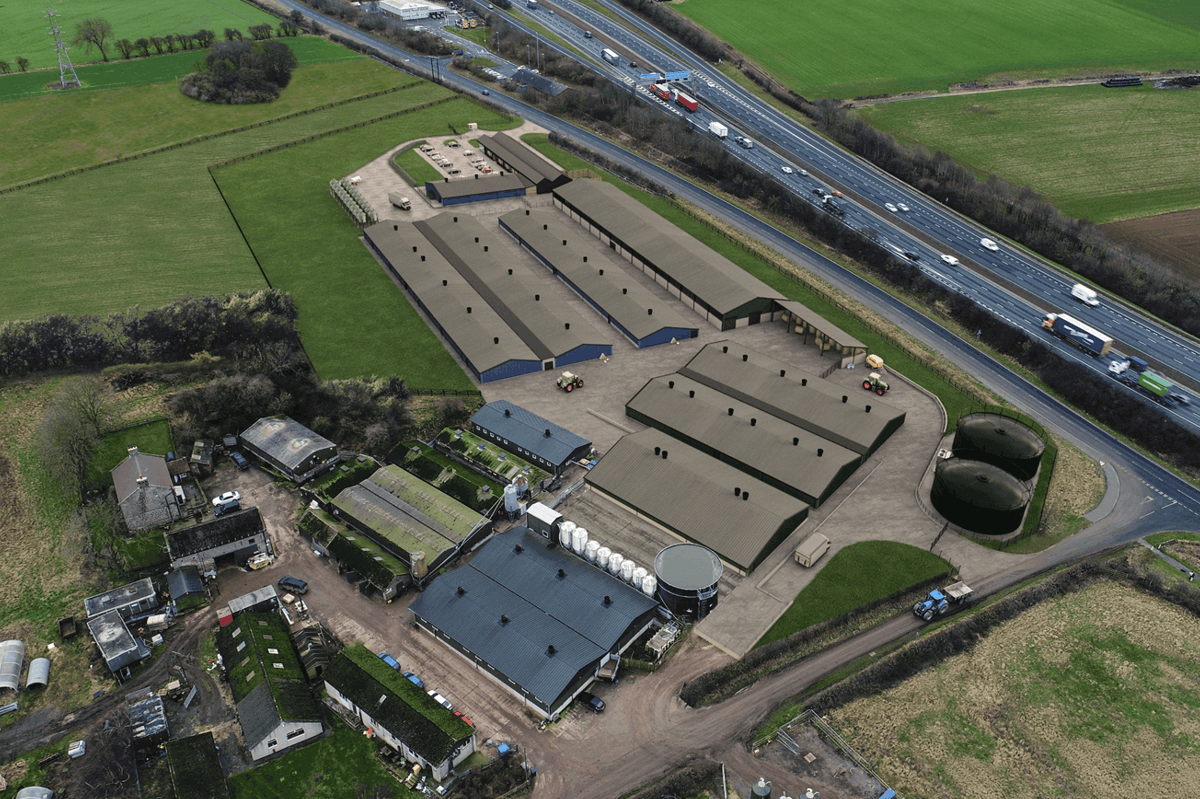

The new state-of-the-art National Pig Unit is located in Leeds (United Kingdom), and is, as stated in the University of Leeds website, « a leading research facility for pig nutrition, behaviour,

The Romillé experimental station changes their simple dry feeding lines to the Asserva efficient pneumatic distribution technology, for a precision and flexibility improvement. A high level of feeding system throughout