CAHE Exhibition save the date !

The China 2022 International Livestock Exhibition, known as CAHE 2022 worldwide, take place a new date 10 to 12 august 2022 due to covid pandemic situation in china. This important

The China 2022 International Livestock Exhibition, known as CAHE 2022 worldwide, take place a new date 10 to 12 august 2022 due to covid pandemic situation in china. This important

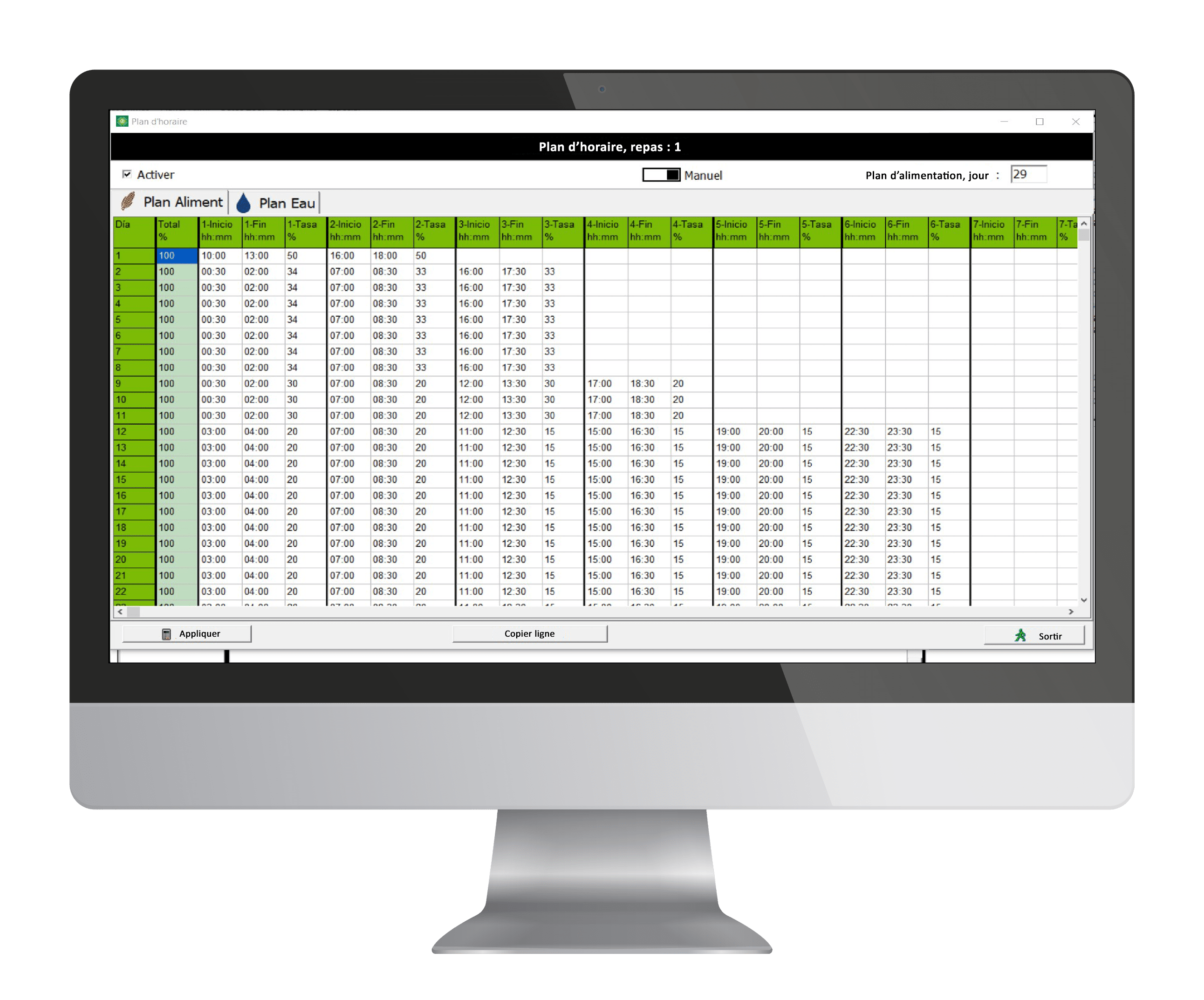

More meals, better management ! Using a pneumatic wheel or electric screw feeder, each ration is delivered in small quantities (100 to 200g) according to the animal’s appetite and ingestion

On Friday, April 1st, Arnaud JOLLY, breeder in Plaintel (22) opened the doors of his farm to present his new 1200 places fattening building. Building on straw BIO model with

New fitting for ASSERVA ! Finishing touches on the soup machine of the Gaec de la Croisière in the Orne department.Installation of the soup machine, pre-soup and cereal grinding with

The British Pig & Poultry Fair will be held at NAEC Stoneleigh Warwickshire from next 10 to 11 May 2022 presenting news from UK and international companies related to the

Segoviano New installation for Asserva in Spain in the Cochinillo Segoviano farm located in the Segovia region.A farm with a capacity of 630 sows with 114 farrowing places and a

Materneo concept Smart feeding and watering system for farrowing sows With a pneumatic dispenser which measure feed with a wheel, each portion is delivered in small doses (150 g) according

Sylvain – Europe export sales manager What is your background ? I am from Finistère, from a family of breeders, my parents and today my brother have a pig farm as

We would like to thank our client, Valery BERTRAND – SCEA DU RIEUX for the confidence shown in the Asserva and Asserva Energies team, regarding the installation of equipment in

Frédéric Baudet is a breeder-fattener in the Côtes d’Armor. A breeding of 300 sows, two sites, 40 hectares of land… Since its installation in 2011, he has not stopped technically

What is your background ? I graduated a Scientific Baccalaureate then a bac+2 IUT Mechanical and Production Engineering in Rennes. After these two post-baccalaureate years, I joined INSA Rennes, a

For a consumption responsible without packaging. The “bulk” consumption mode is defined by the purchase of products without packaging. Today, discarded household packaging in France represents 55 kg per capita

Asserva fitted at ghent university, with 10 aqualab stations with animal weighing. The building consist of 10 crate of 15 piglets.The piglets will be brought in at 7 kgs and

Agro Animal Show is the most important platform for animal husbandry and agricultural technology in Ukraine. At the last edition, 534 companies from 23 countries showed their complete range of

Thanks to Gilles and Marie Agnès for their welcome and the planning day. Gilles Fassot is definitely not a breeder like the others. Owner of the Kerbic farm, he began

Twelve Catalan farms received fourteen Golden Pig awards this Friday, which recognize excellence in pig production, at a gala that brought together 600 professionals in Lleida Lleida once again hosted

Documentation (content and accessibility) A first stage of the technical documentation has been achieved this year, every product has its own construction guide and operation manual. We are now working

New fitting in Spain for Asserva Installation of the Optimat Air concept – Multiphase pneumatic transfer in the Los Cortijos farm with 18 rooms for 21,000 piglets from 6 to

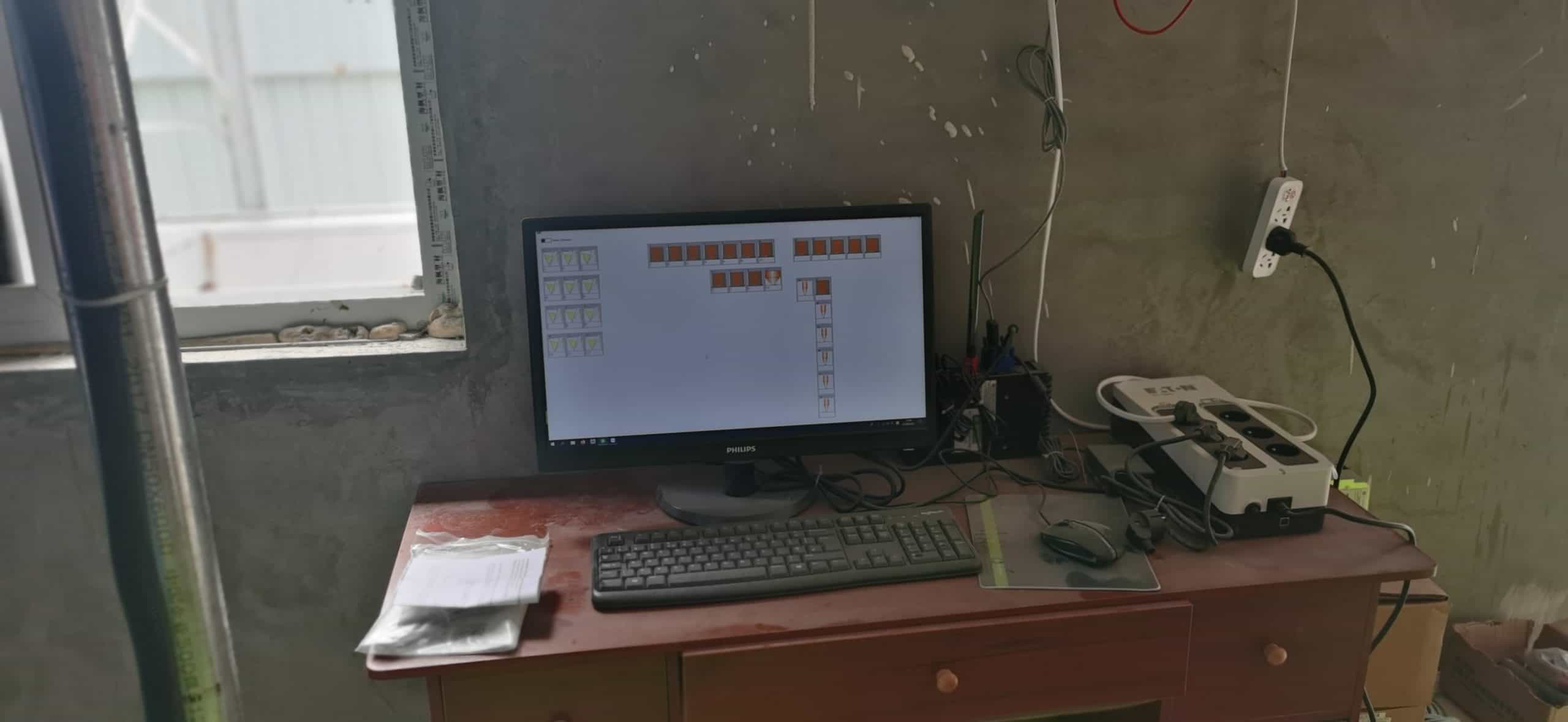

The ASSERVA development in China still going in the good way, the chinese farmers and the the chinese livestock companies request new solutions and high technologies. ASSERVA company takes market

Deployed for fattening pigs, the Selfifeeder GFI feeding station controls the quality and quantity of feed distributed as well as the weight of each animal. Equipped with an identification system,

On the strength of its competitive position and its new notoriety in the Spanish market in recent years, Asserva company participated at FIGAN 2021 in Zaragoza with a booth 2.5

After several months and the cancellation of SPACE 2020, we was really excited to welcome you in our Booth during the SPACE 2021 at Rennes (France). With still the impressive

After some weeks of installation, the liquid feeding system for 20 000 fatteners is now under commissioning by our chinese ASSERVA technician. The system is divided in 2 parts with 2

To improve our services and to insure an important business development, a new ASSERVA technician join us in China. Aiden has 8 years of experience in automation as Equipment maintenance

Finally ! After a virtual edition in 2020 due to the sanitary situation, the famous SPACE Fair, one of the main international exhibition for animal production, is back ! Located in Rennes

Sure he is a man of experience : Xavier Cordon works for Asserva since more than 30 years ! He is now one of the 3 shareholders of the company, and is

Neighbour disputes ? Printalys is an innovative concept to limit the unpleasant farm odours – inside and outside the buildings. How does it work ? It’s very easy : an automatic system diffuses

Optimat is the multiphase system of Asserva. It works with a classical disk chain (Optimat Mechanic) or with a pneumatic system, where the feed is pushed by air (Optimat Air).

With more than 200 000 visitors, the CAHE exhibition at Nanchang city was an impressive show ! From several years, ASSERVA company with its local team introduced our Intelligent technologies to the

Philippe started to work for ASSERVA in 1992, as an electrical technician. Focused to make general electrical cabinet and electrical infrastructure rehabilitation, Philippe was also on site into the farms.