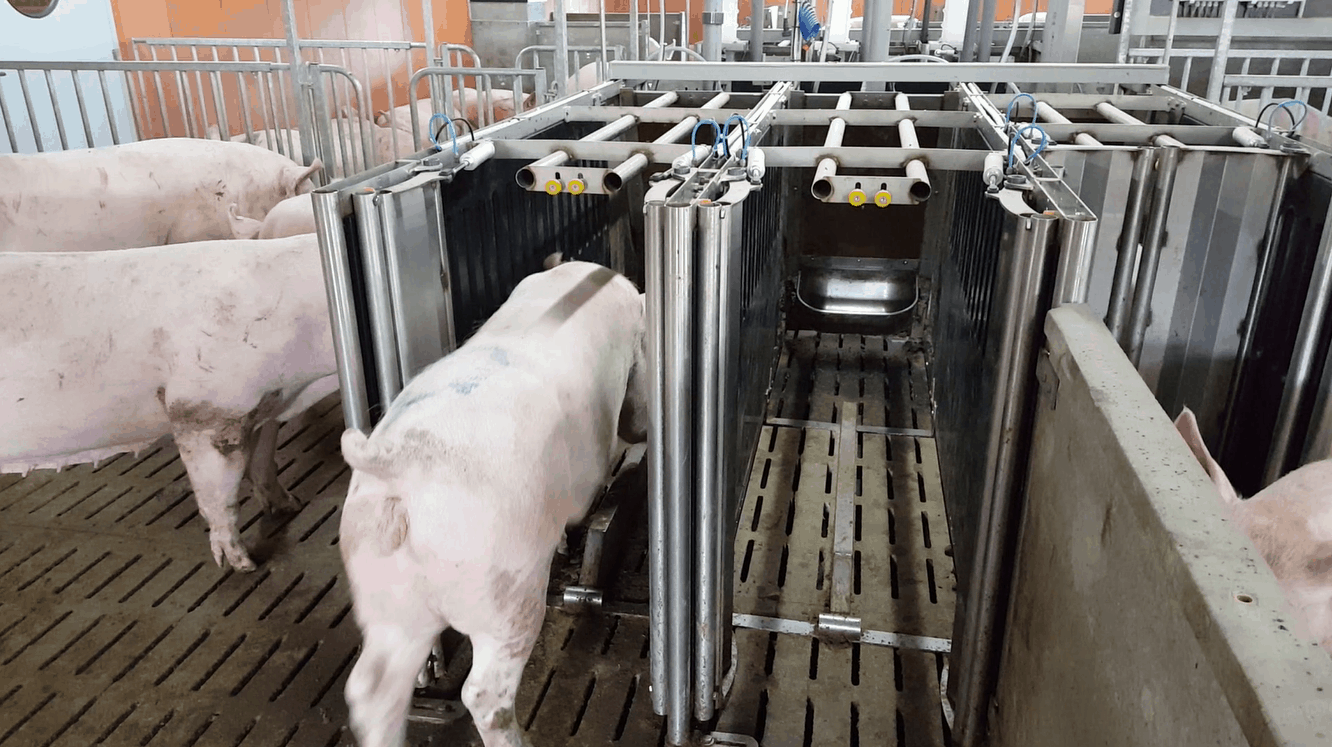

More homogeneous pigs with automatic feeding stations Selfifeeder GFI

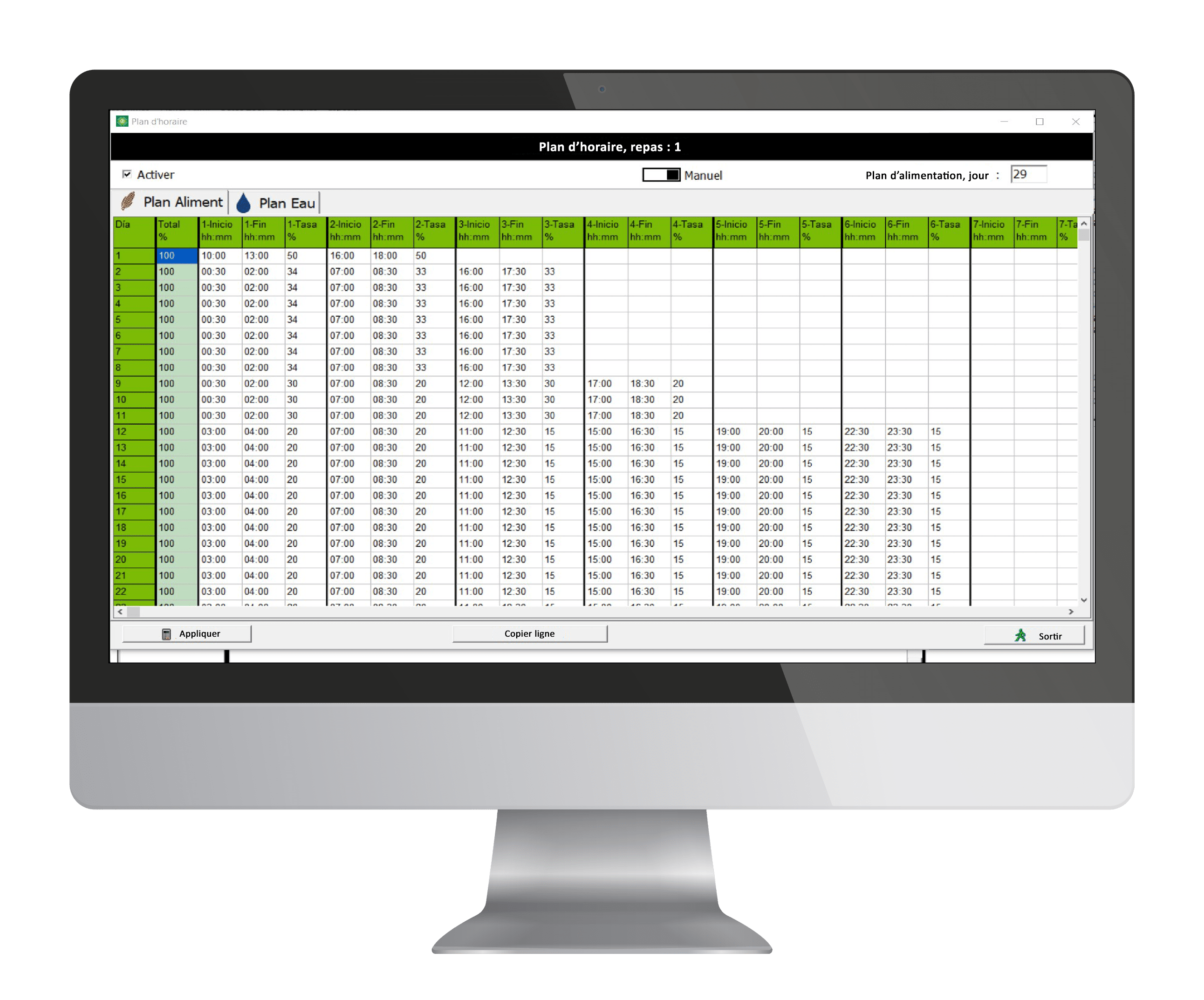

Maximize Your Yield: Achieve 96% Uniformity with Selfifeeder GFI.Stop relying on visual assessment—the future of profitable pig finishing is automated precision! Asserva’s GFI selfifeeder system ensures maximum consistency and logistics