“With Asserva’s Selfifeeder GFI individualized feeding station, I optimize both my working time and the precision of my production batches.”

— Jean-Michel LANGLAIS

(From the article “With Asserva’s Selfi GFI station, I optimize my working time” published in Réussir Porc)

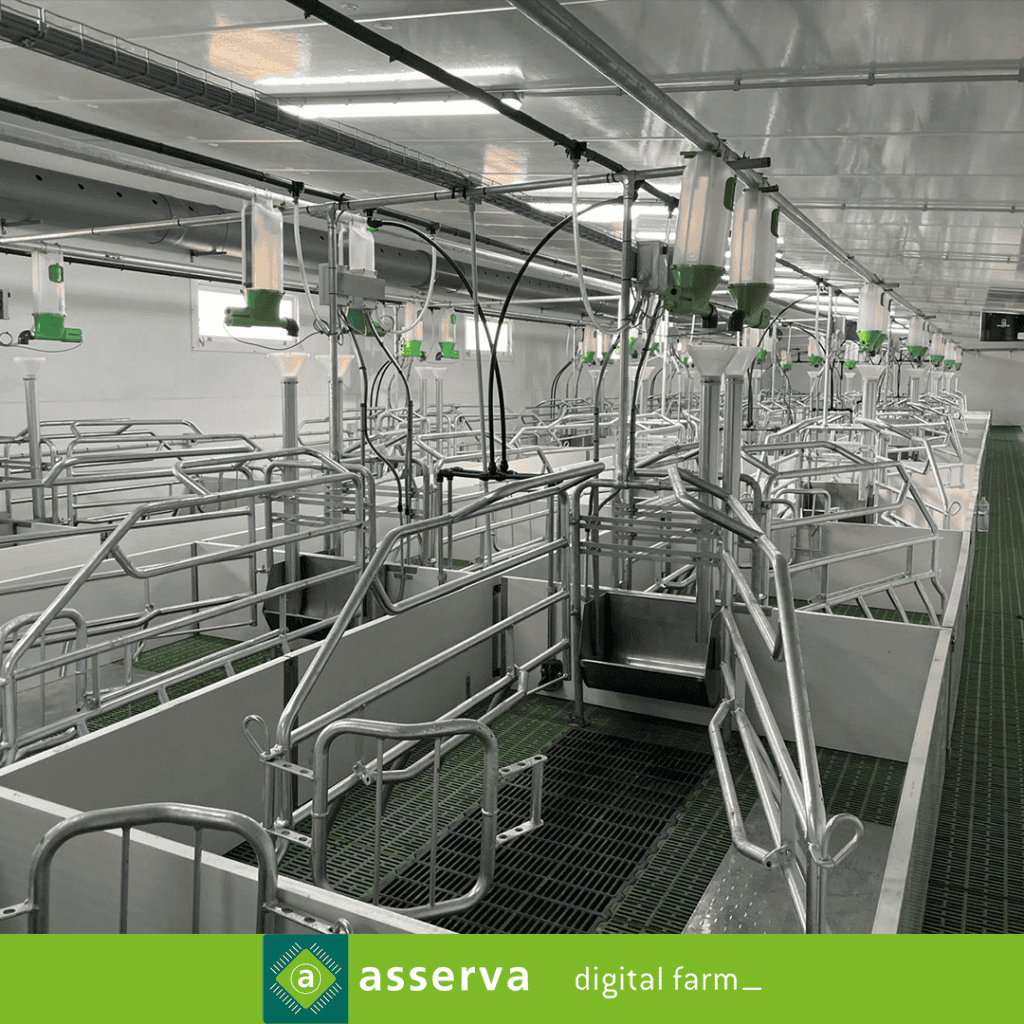

We chose to work with Asserva and its Selfifeeder GFI solution to equip our finishing unit, built in 2023. Our objective was clear: maximize animal performance while simplifying farm management.

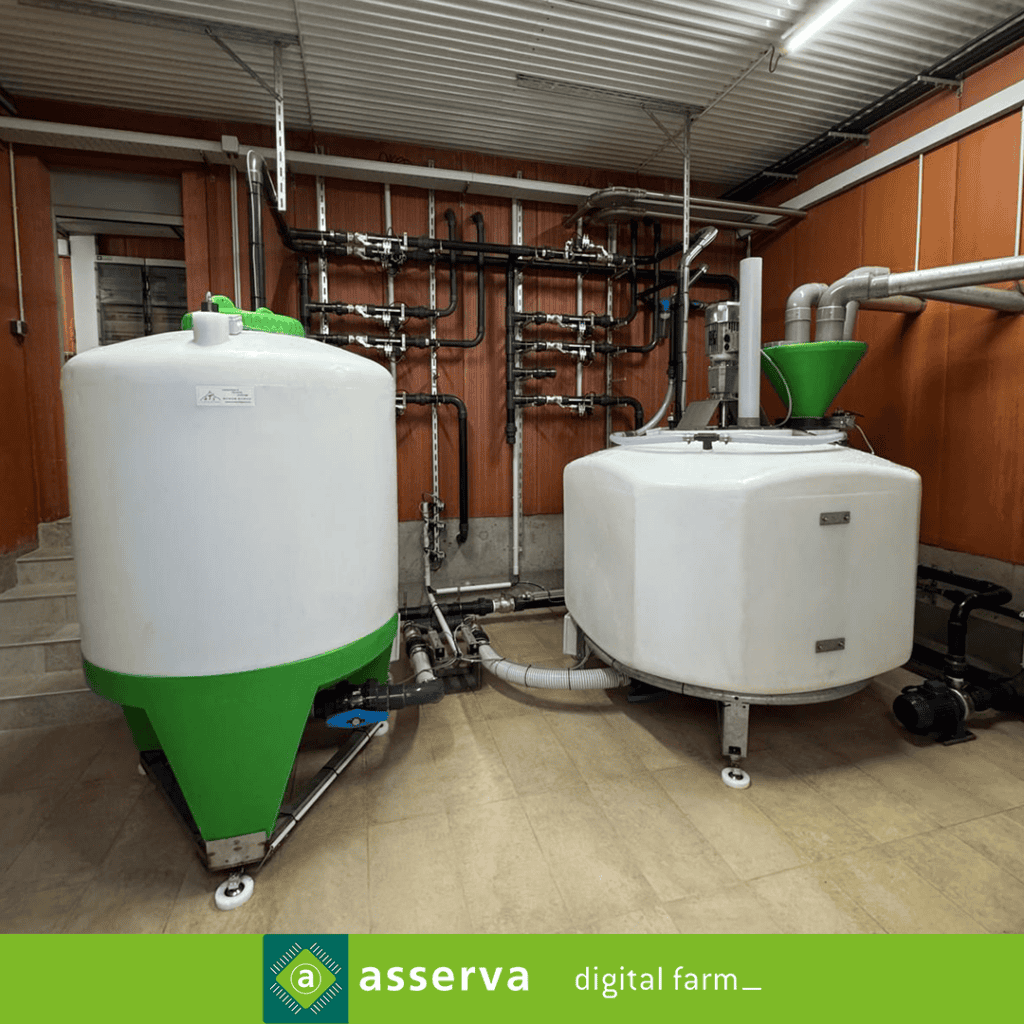

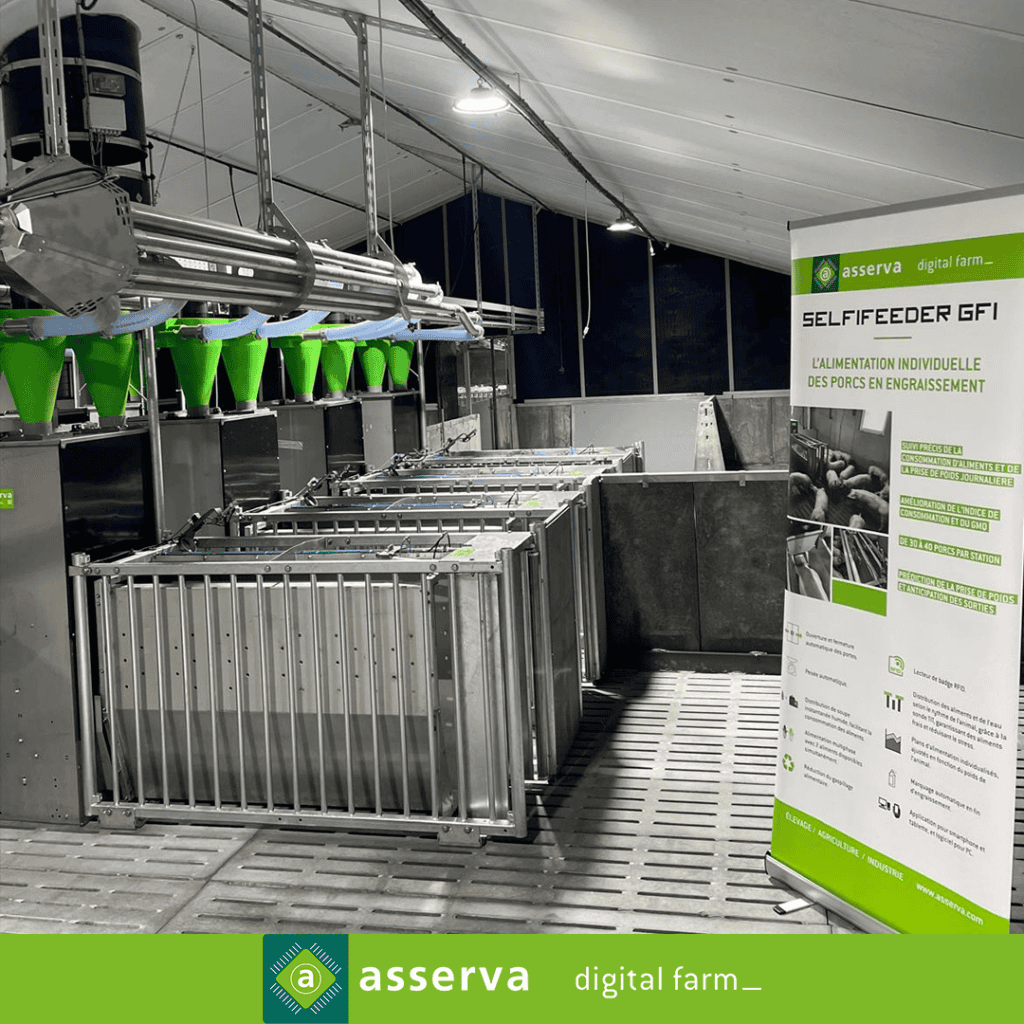

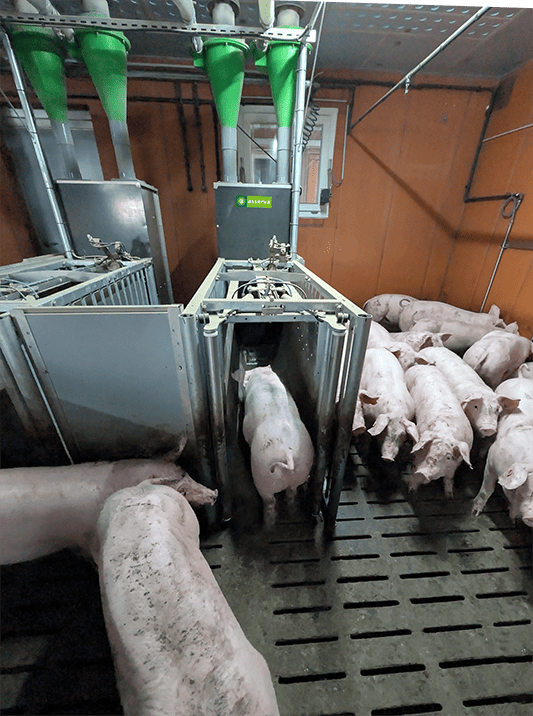

The Selfifeeder GFI station enables individual, rationed, and multiphase feeding for finishing pigs. Thanks to its RFID identification system and automatic weighing, each pig receives a customized feed allowance precisely adjusted according to its live weight. This setup not only improves feed conversion ratio (FCR) and average daily gain (ADG), but also significantly reduces feed losses and waste.

The most impressive impact concerns our labor organization. Before installing the Selfifeeder GFI, sorting 250 pigs used to take us around six hours. Today, thanks to the stations, sorting time is reduced to almost nothing.

Linked to the weighing system, the station is programmed to automatically identify and mark pigs as soon as they reach the target market weight we have defined. The system’s software allows extremely accurate selection by weight. The results speak for themselves: we now achieve 96% of pigs within the optimal target range.

The Selfifeeder GFI also provides detailed analysis of each animal’s feeding behavior (number of visits, feed intake, daily weight gain), giving us precise insights into the herd’s zootechnical performance and facilitating production planning.

We highly recommend Asserva’s Selfifeeder GFI stations. They are the ideal solution to provide “the right amount of nutrients to the right animal at the right time”, while enabling us to greatly optimize our working time.