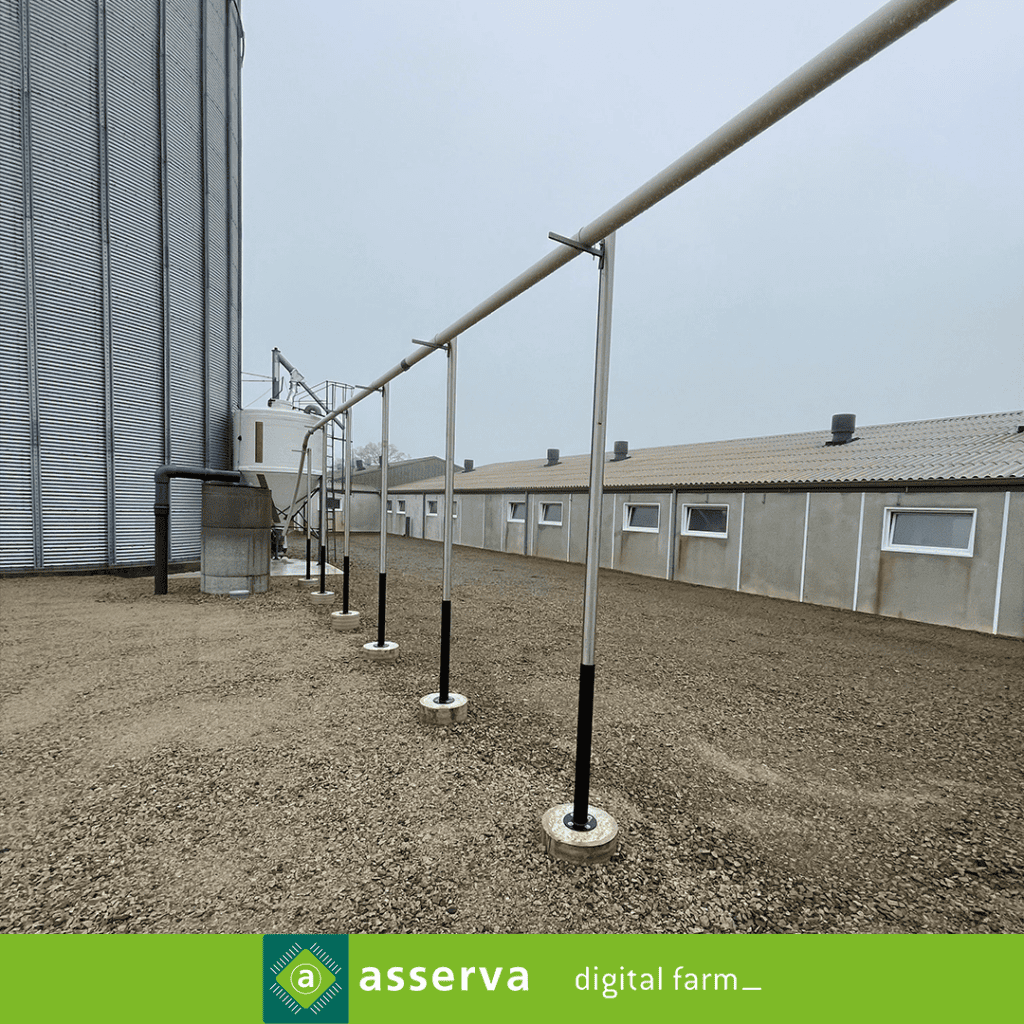

On Friday, February 13, 2026, GAEC Ruchères hosted an open house to mark the commissioning of its new maternity and post-weaning buildings, along with a new feed mixing room.

The event allowed visitors to explore a modern facility designed to combine technical performance, animal welfare, and energy efficiency.

A Modern and Well-Sized Production Facility

The project includes:

- 🐷 72 maternity places

- 🐷 1,024 post-weaning places

The goal was to equip the farm with high-performance, durable systems that optimize pig management while ensuring optimal conditions for the animals.

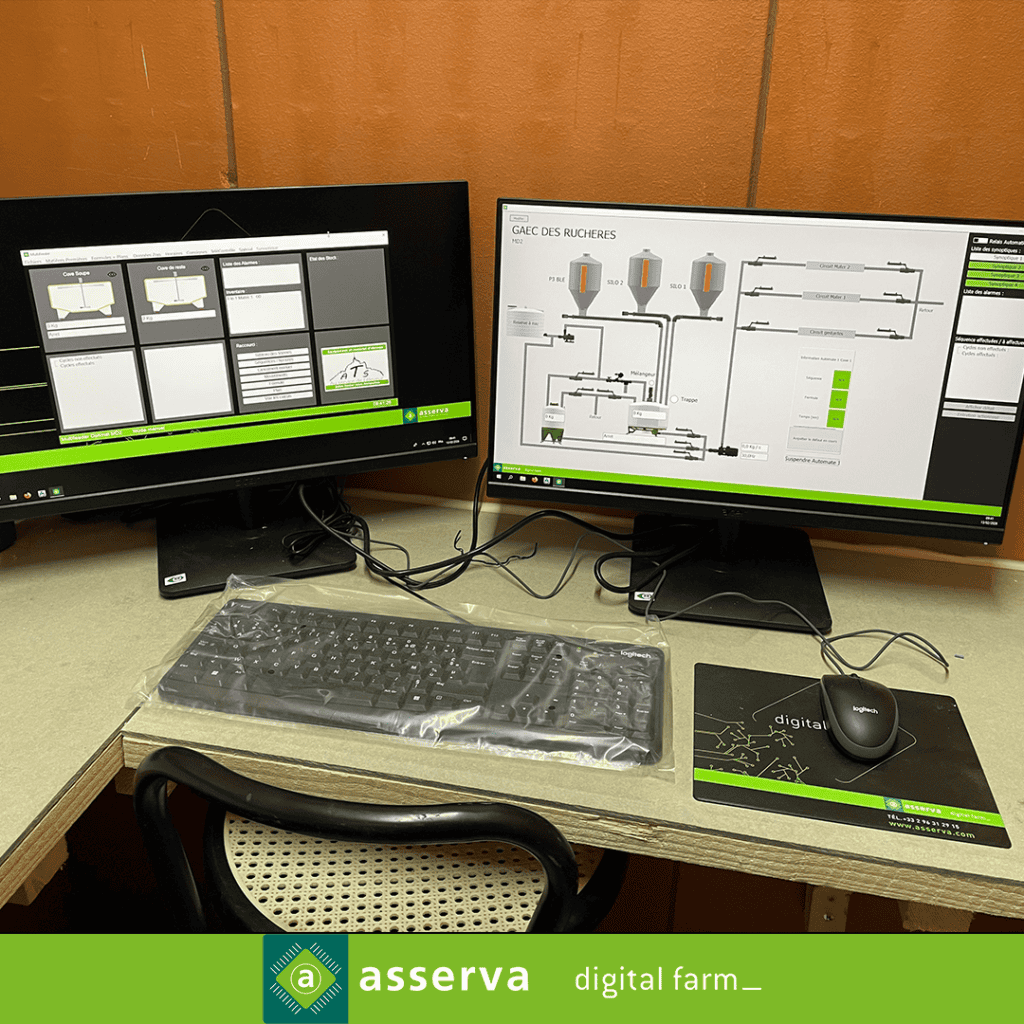

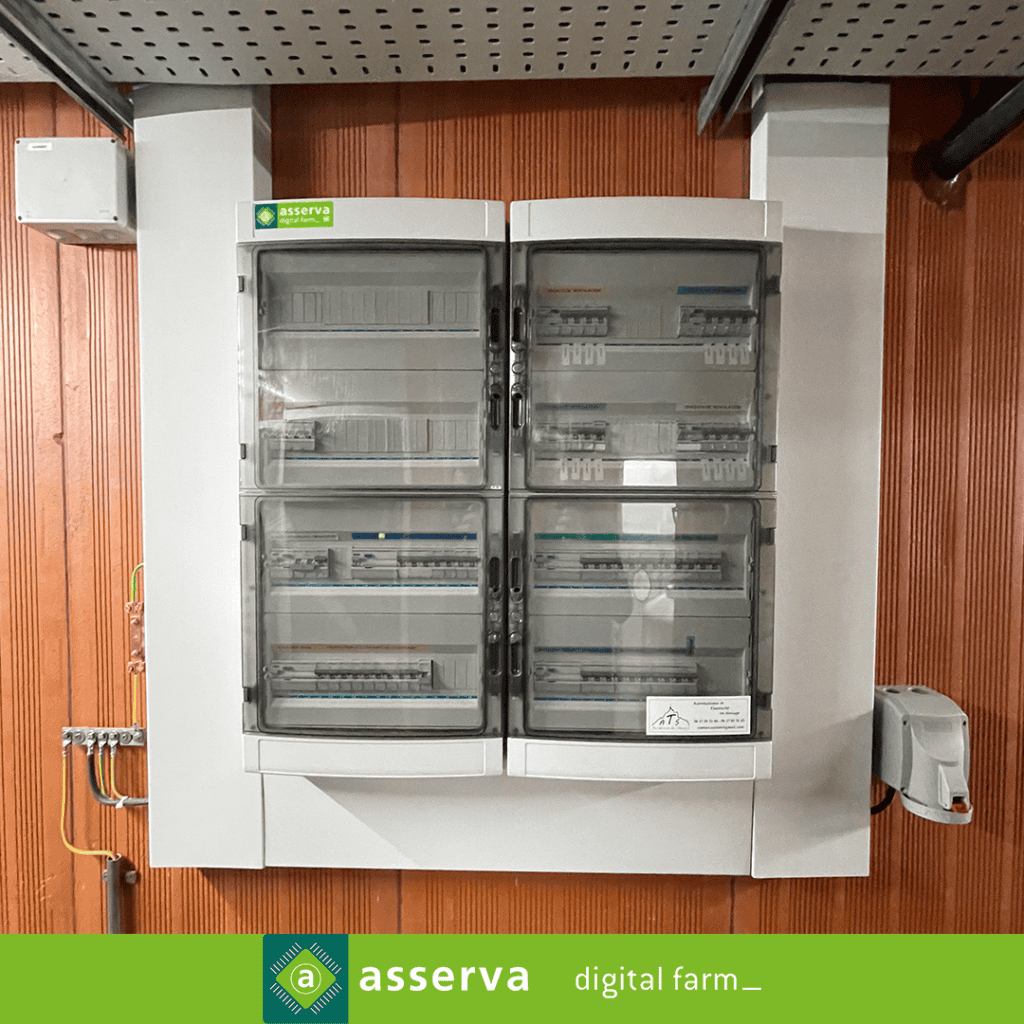

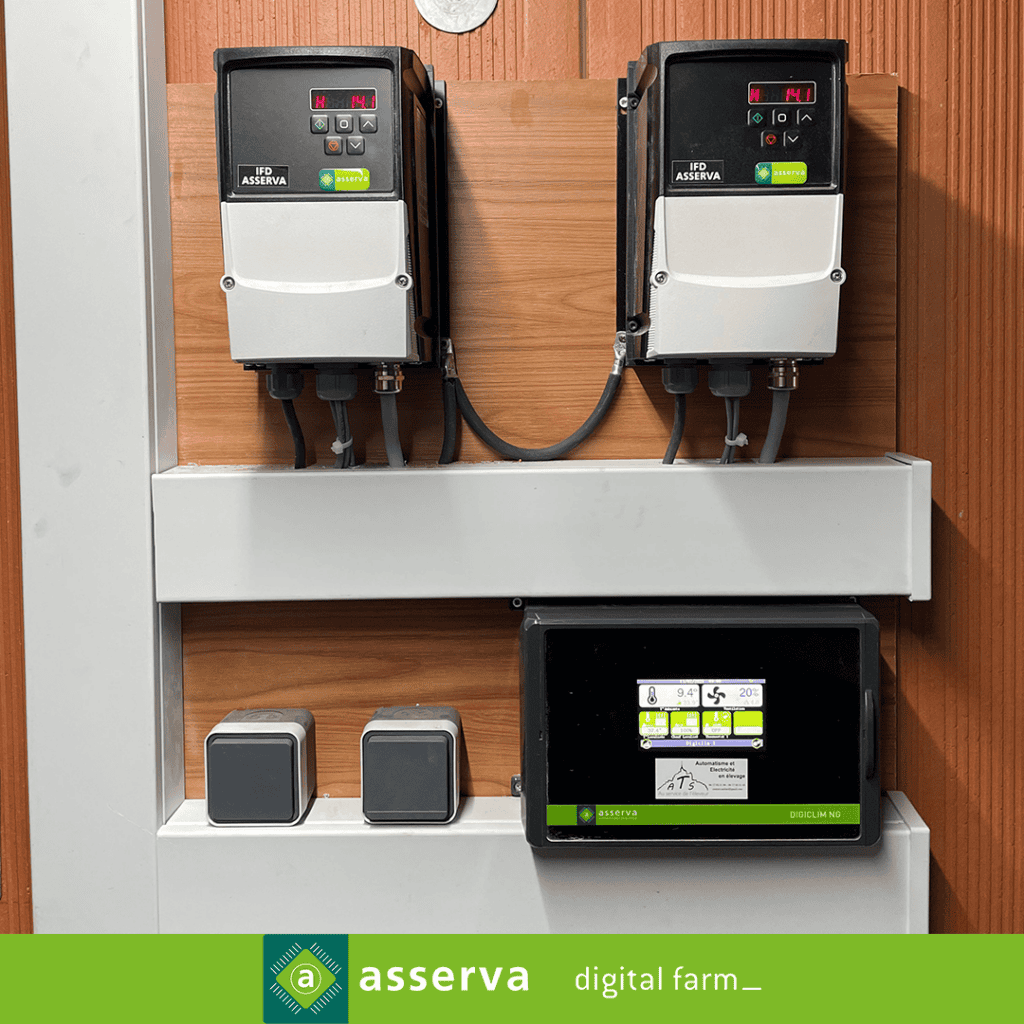

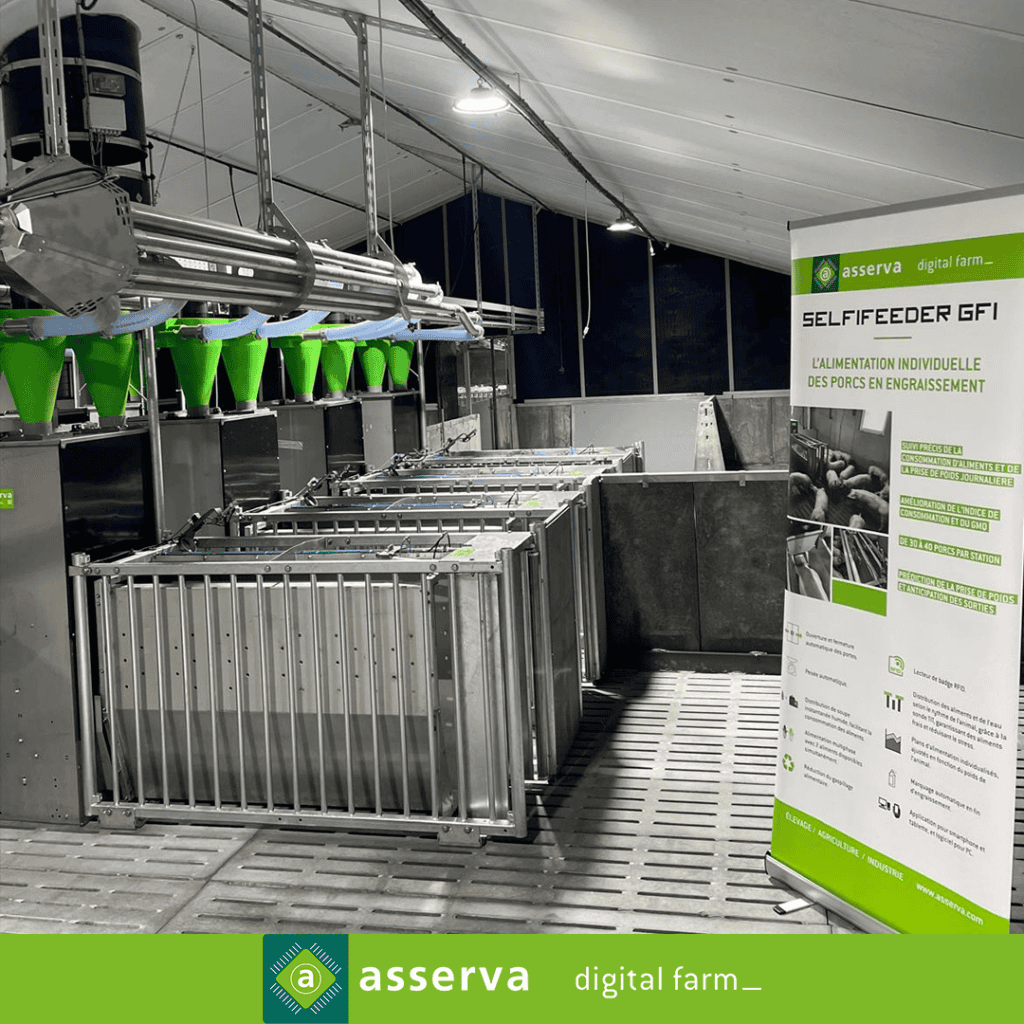

A Complete Installation by Asserva

The Asserva equipment was installed by SARL ATS Automatisme Technologie Service, a recognized partner known for technical expertise and quality implementation.

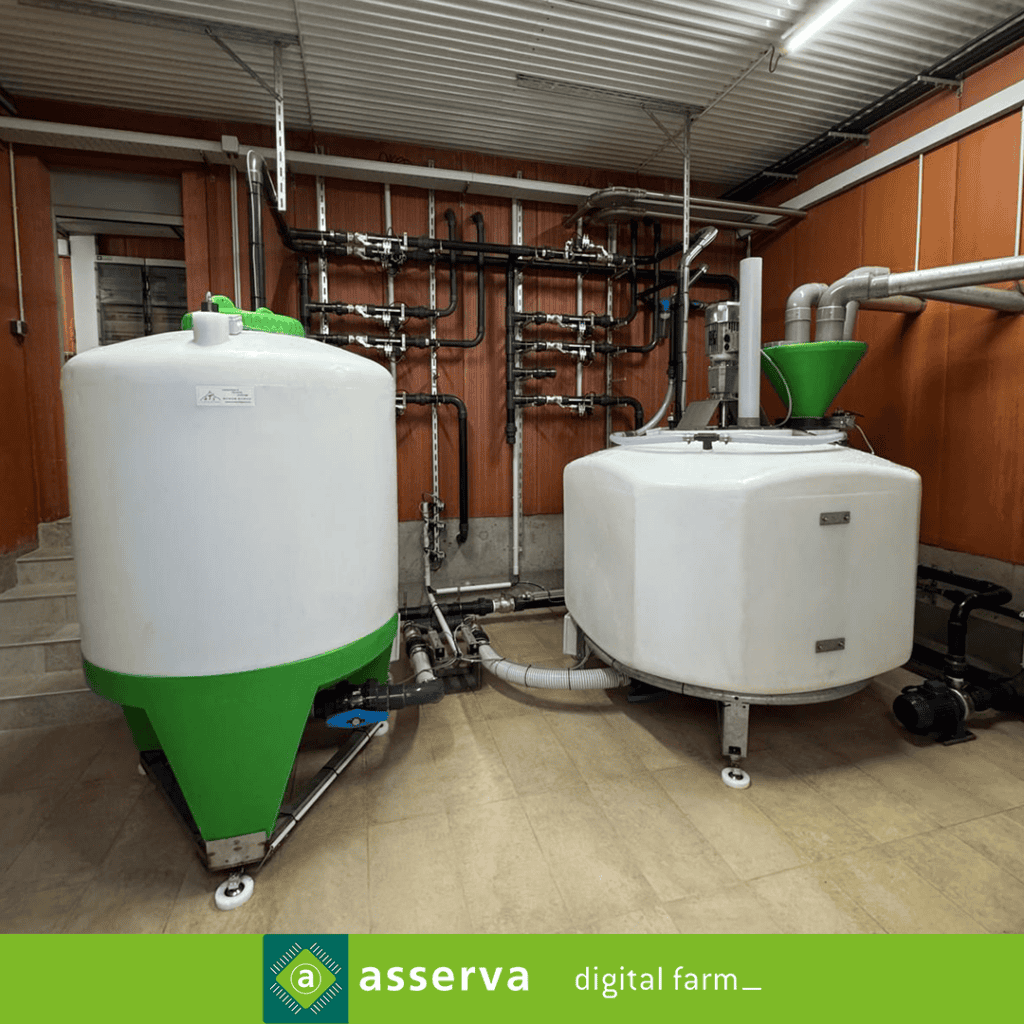

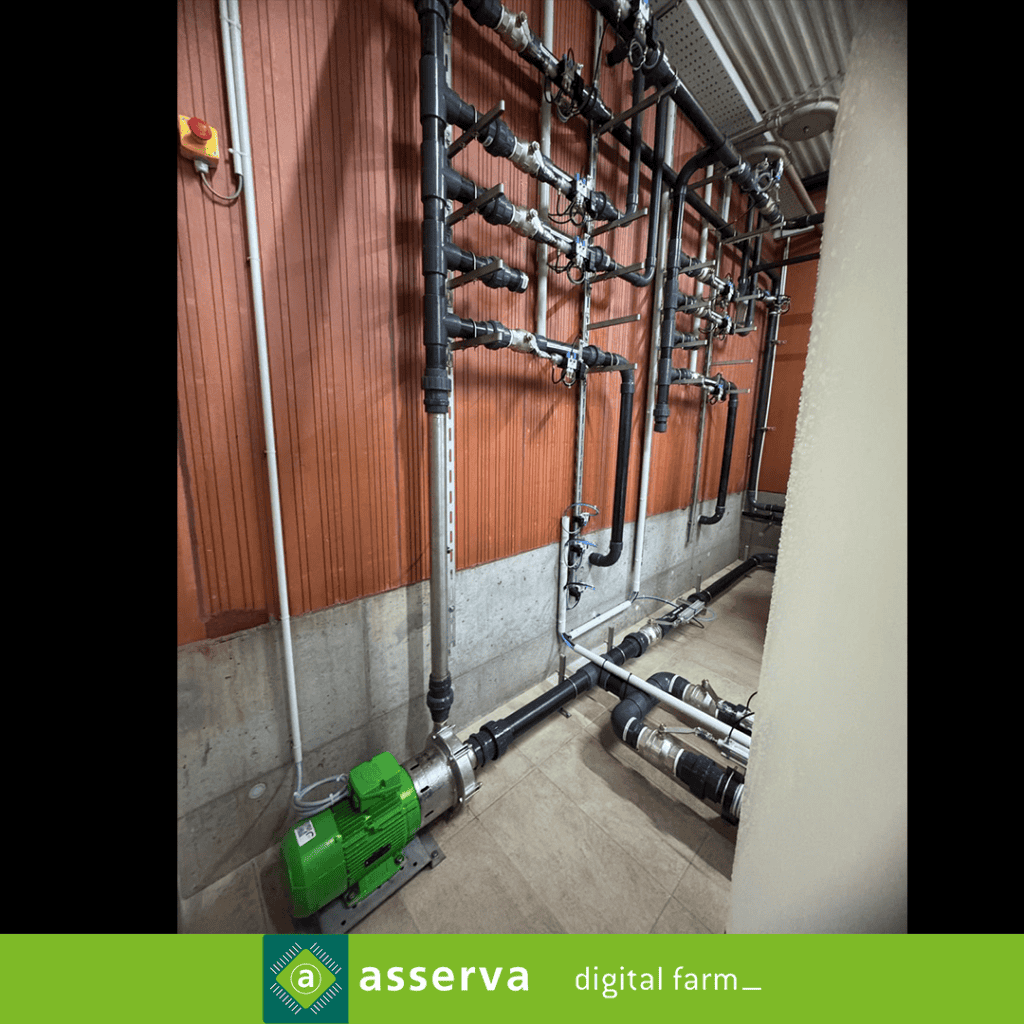

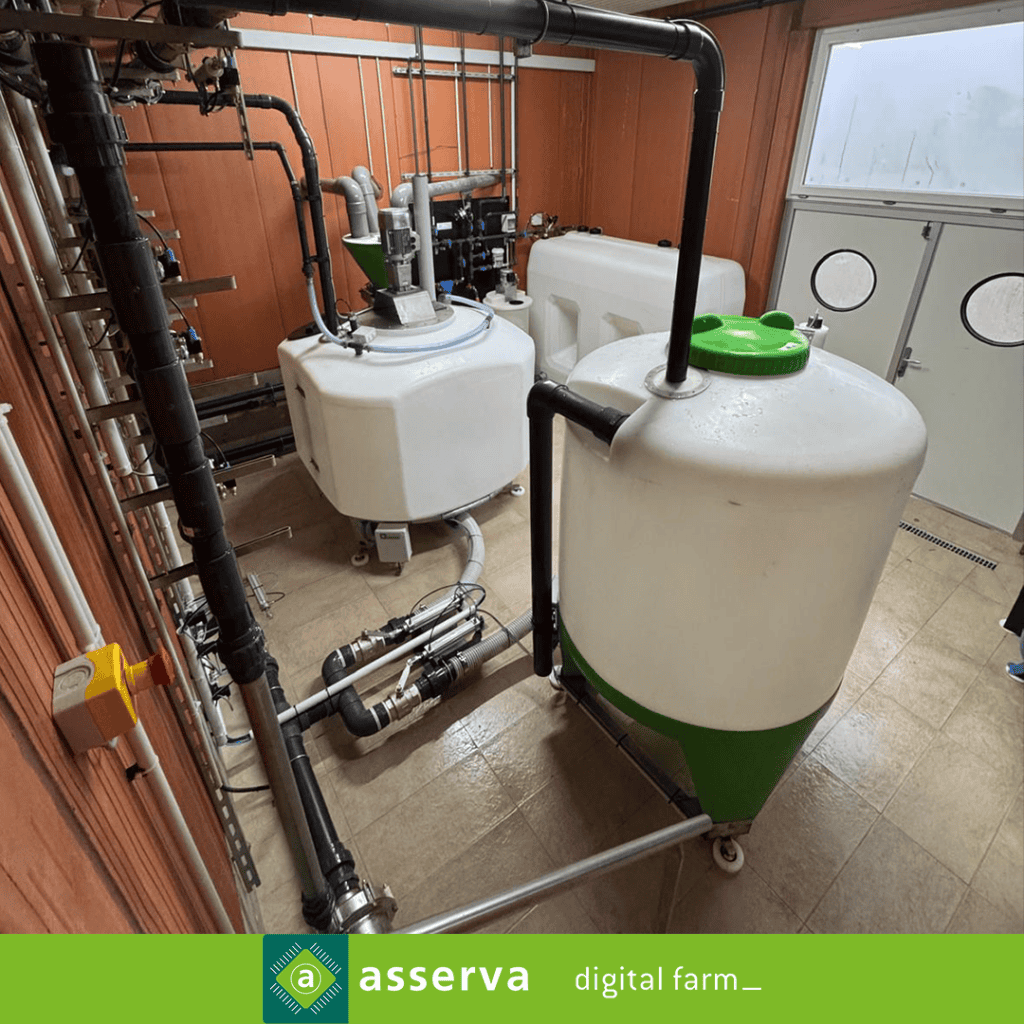

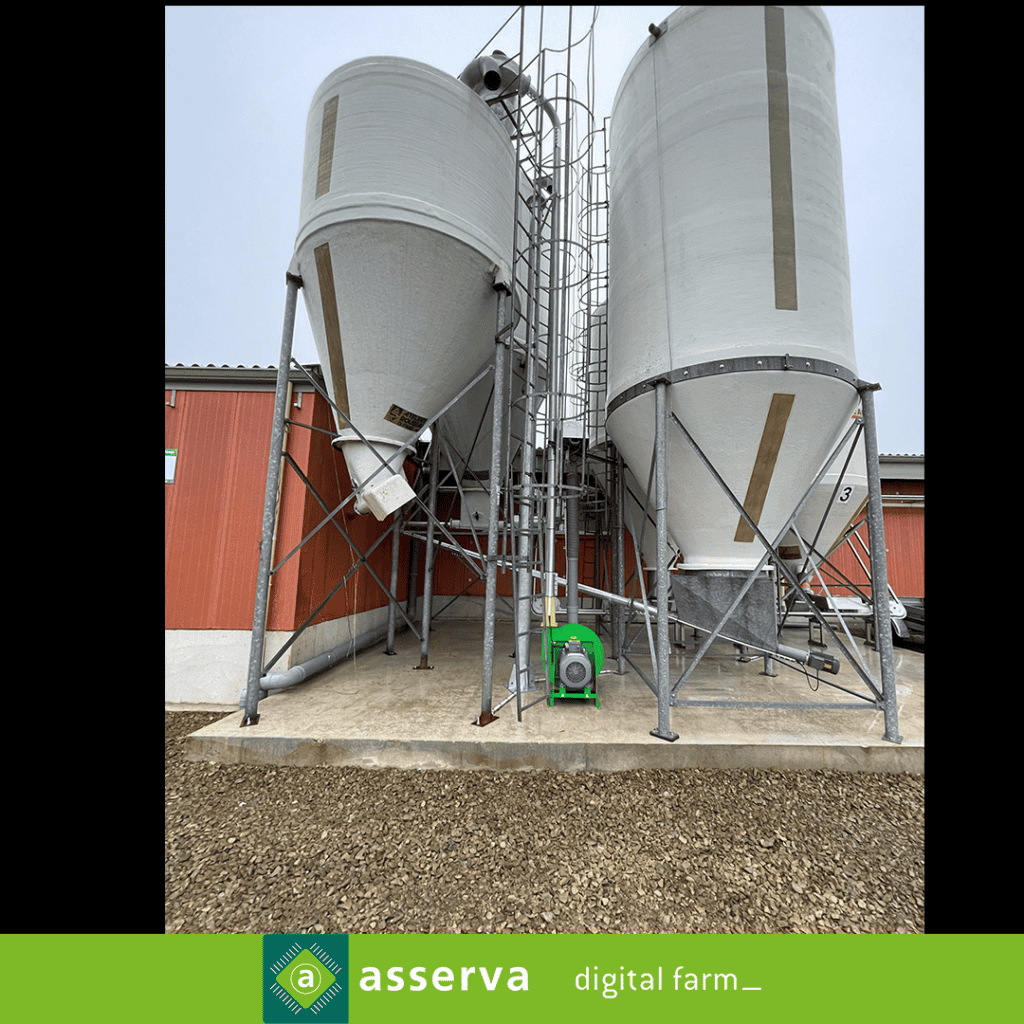

🔹 Feeding and Preparation

The system includes:

- A new feed mixing machine for maternity and gestating sows, with a weighed leftovers tank

- Sleeve valve distribution for precise and reliable feed delivery

- A cereal pre-grinding system

- Two pelleting lines for post-weaning feed

These solutions ensure efficient feed management and better utilization of raw materials.

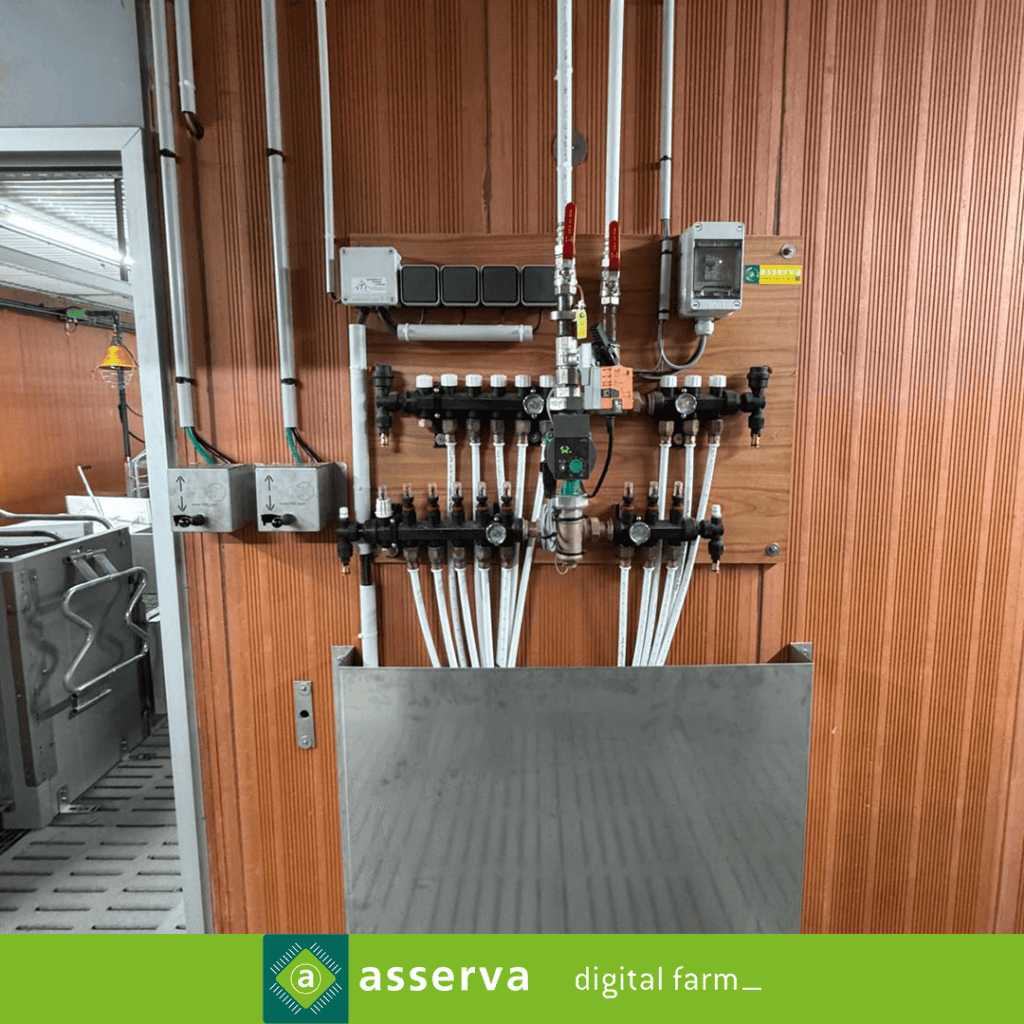

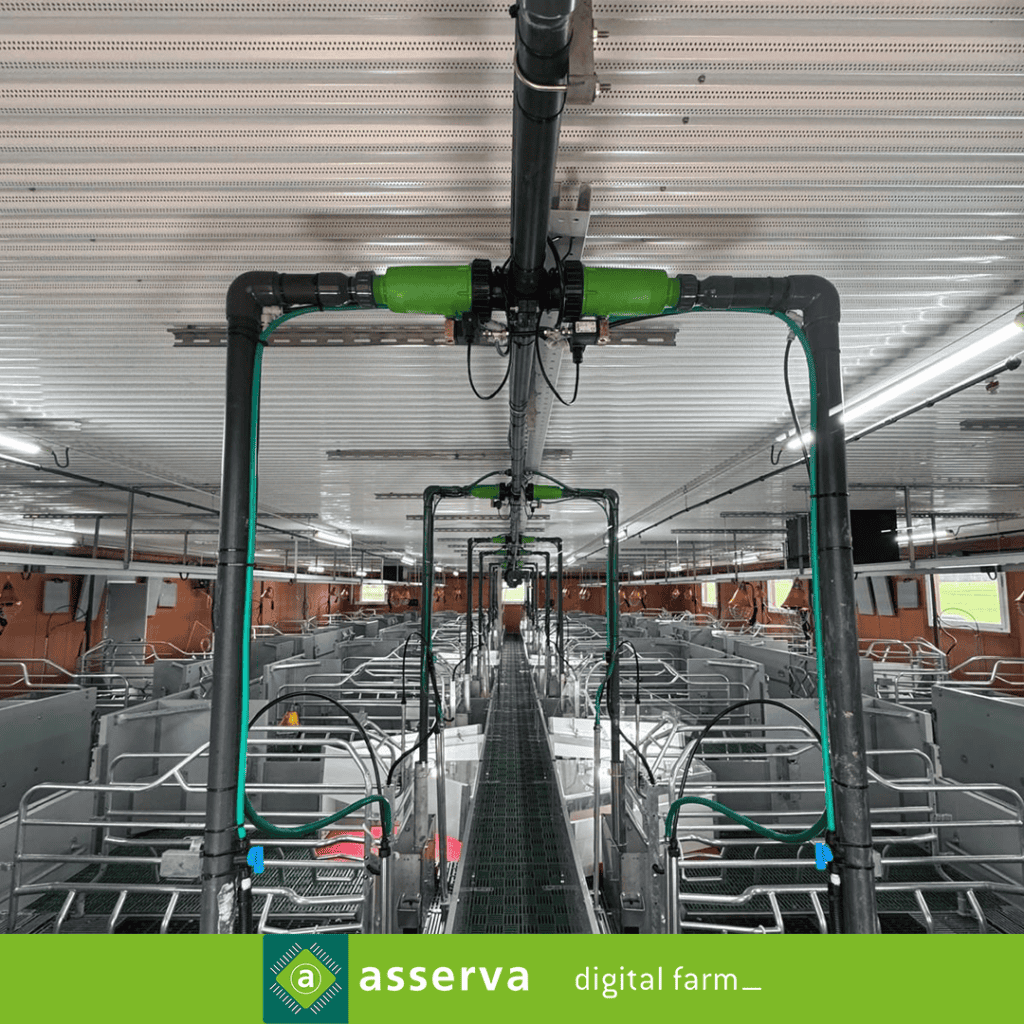

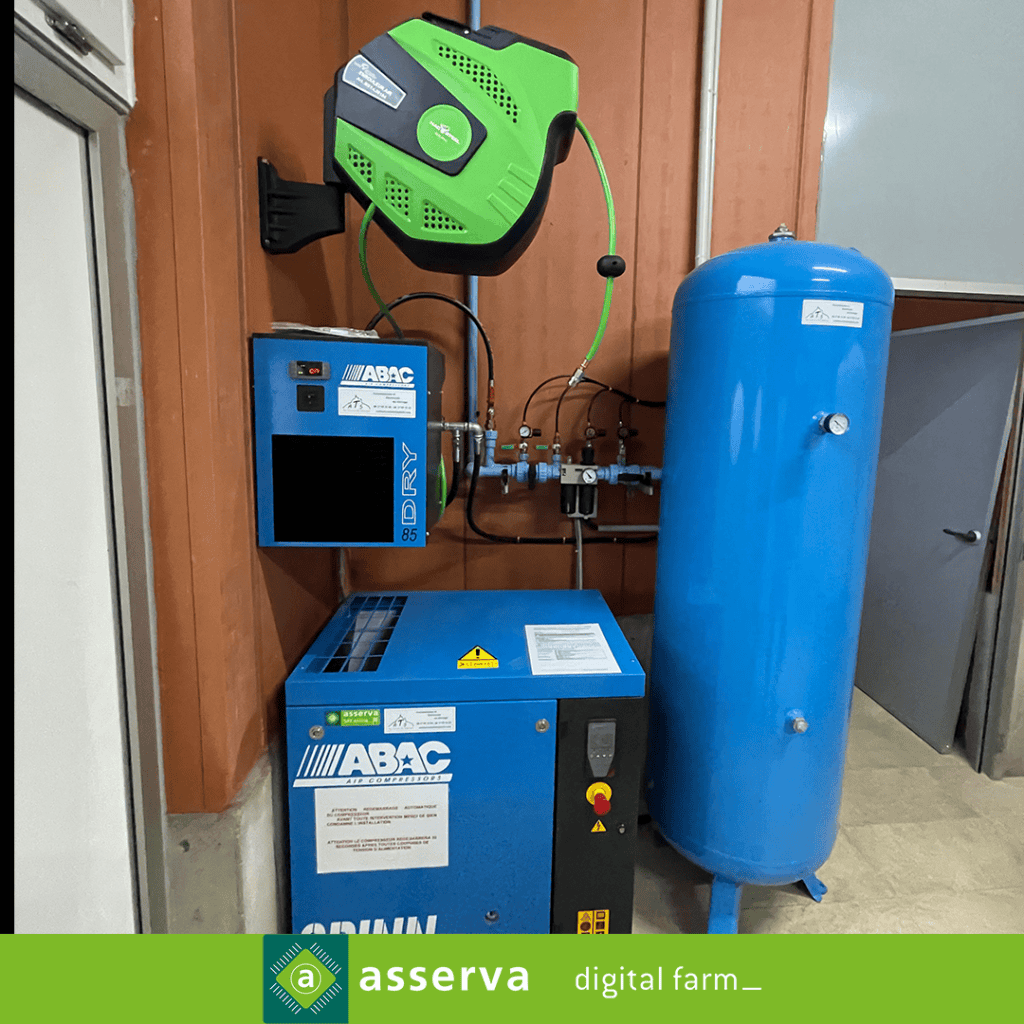

🔹 Technical Equipment and Animal Comfort

The installation also features:

- Energy-efficient ventilation

- Safety windows

- LED lighting

- High-pressure network

- Soaking system

- Drinkers connection

- Fully equipped sanitary facilities

All of these elements contribute to better working conditions and improved animal welfare.

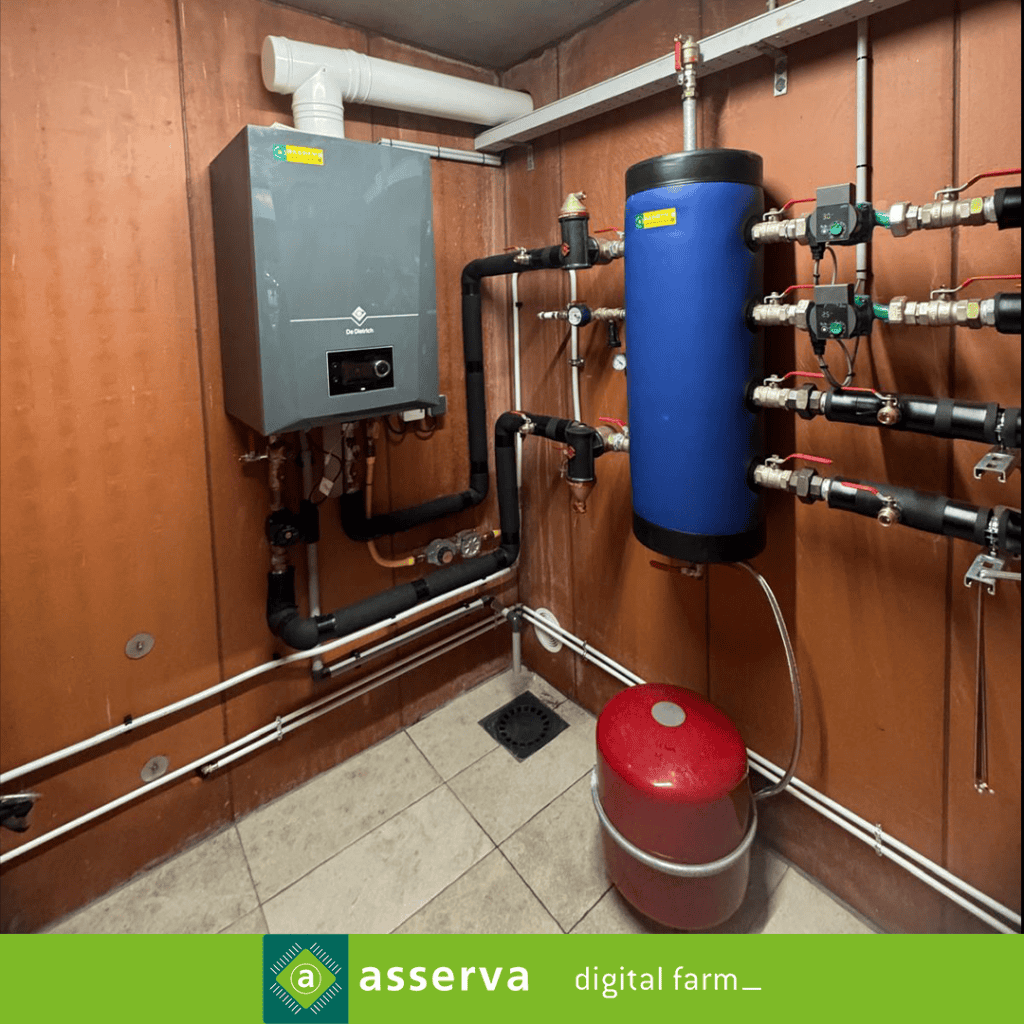

Controlled Energy and Heating Systems

Energy performance was a key focus, with:

- 🔥 61 kW propane gas boiler

- 🔥 72 hot-water plates in maternity for sow comfort

- 🔥 Ambient heating for 1,024 post-weaning places (Spiracier piping)

- 🔥 Heating for sanitary facilities

These systems ensure precise temperature control, essential for both maternity and post-weaning areas, while providing efficiency and reliability.

A Successful Collaborative Project

The open house highlighted a transformative project for the farm, combining modernity, performance, and animal comfort.

We sincerely thank GAEC Ruchères for their trust and SARL ATS Automatisme Technologie Service for the quality of the installation and their commitment to making this project a success.